One of the components of this season’s research programme on Pine Island Glacier is the ice core drilling. Here Becky Tuckwell explains how it works:

Ice cores from Antarctica are important to help unlock past climate records and to reveal historic records of snow accumulation to name but two of their important uses. But drilling ice cores in Antarctica requires a large complex operation to get the equipment out into the field, assemble it and begin drilling. Once drilling is underway, we drill intact columns of ice, 1 or 2m at a time, and then process the collected ice for storage and transport north (still frozen), where it is analysed in laboratories back in the UK.

These reasons were why I was completely surprised (besides being beyond excited and nervous) to be given the opportunity to travel to Antarctica in spite of having nil ice core drilling experience. With the with the iSTAR team, we were going to traverse across the Pine Island Glacier in West Antarctica to drill ten shallow (~ 50 m) ice cores at different sites. Of course I am not drilling on my own. I get to work with ice core drilling expert Robert Mulvaney and the rest of iSTAR-C team. It is a group effort and everyone has pitched in at all stages of the drilling equipment assembly and process (Thanks to Izzy, Seb, Andy, both Alex’s, Damon, James, Tim, Emma and Mark).

Previous BAS drilling projects (e.g. Berkner Island, 2002-2006) have been aimed at obtaining deeper ice (e.g. the ice core collected at Berkner was 948 m in depth) and this requires working for months (and many seasons) at the same drilling site. The iSTAR project differs from this in that we are moving overland to collect shallow ice cores from multiple sites in a 12 week field season.

Traditional ice coring projects are static. They work at one field site for an entire field season. Being part of a travelling project, however, presents us with a host of new challenges as ice core drillers; we have to transport all our science and living equipment and the collected ice cores along with us as the iSTAR traverse moves from site to site. Furthermore, our drilling must fit in with the larger science program being carried out along the way.

Pisten Bulley snow tractors form the mechanical heart of this traverse. Driven and maintained by Tim and Mark, the “PBs” successfully haul all our living gear, science equipment, ice cores and our luxury caboose (shipping container fitted with a kitchen and comfy seating area for 12) from site to site. At times we have reached a speedy 20K/hr whilst travelling over the bumpy sastrugi and I don’t think we have lost anything or anyone along the way as yet.

On arrival at each site we have to set up camp (made a lot easier with our experienced traverse leader James) and get all the required science equipment ready for collecting ice and data. We have now been in the field for over a month (21 days until Christmas!) and are at site 17. To date we have completed our scientific objectives at 5 of the intended 22 sites, including seismics, radar arrays and neutron probes. All of this has been accomplished despite high winds (up to 40 knots), low visibility and very cold temperatures (coldest: -32 ⁰C) holding up procedures at times. We have also successfully drilled 50m ice cores at two of the ten planned iSTAR sites.

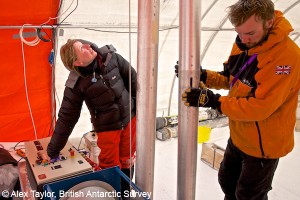

The first thing we do at an ice core drilling site is put up a large tent which enables us to work in most weather conditions. The drill itself is transported in segments (Anti-torque, motor, outer barrel, inner barrel sections and the drill head) which we assemble once the tent is up. The tent comes complete with a hole in a roof. This is not a mistake but accommodates the mast. Together with a winch, the mast is used to hoist the drill up and down the hole.

The drill system bores down into the ice 1m at a time, tended at the surface by two operators on the controls. The sharp teeth on the bottom of the hollow drill head spins in a circular fashion, cutting down into the ice as it goes. This creates a cylinder of ice inside the hollow tube of the drill – this cylinder is the ice core itself.

After cutting through a meter or more of ice, the drill is raised from deep within the hole, bringing up the ice core with it. The inner barrel is released from the corer tube and we push the 1m column of ice out. The drill is then sent back down the bore hole to drill down a further 1 m. This process is repeated again and again, one meter at a time, to collect all 50m of ice we are seeking.

We record the weight, length and diameter of each 1m core. These measurements are used to calculate the density of the ice. We then cut the intact cylinders of ice into sections with a band saw, seal them in labelled bags and store them in proper sequence in insulated boxes ready for transportation.

The ice cores won’t be transported out of the field to Rothera Research Station until the end of the Antarctic summer. In that time they must remain well frozen, below -18⁰C, to preserve their structure. This presents difficulties to us iSTAR ice core drillers (I think I now qualify as one after drilling 100 m of ice): the Antarctic summer will present us with temperatures higher than -18⁰C. Balmy temperatures of -8⁰C have already been reached here at Pine Island Glacier this season. This is cause for concern, as we need to preserve the chemical integrity of the ice cores to ensure we can achieve reliable data once back at the laboratories in Cambridge.

Fortunately, here in the field, a cold freezer is always available underground. Buried out of reach of the sun’s rays and surrounded by cold, insulating, dense snow keeps the cores in the temperature range we need. Unfortunately for me this will entail of lot of digging, as burying the large ice core boxes is not easy task. As we need to dig up the cores each time we move the traverse I am expecting to be just as good at digging as well as drilling by the time I return to the UK!